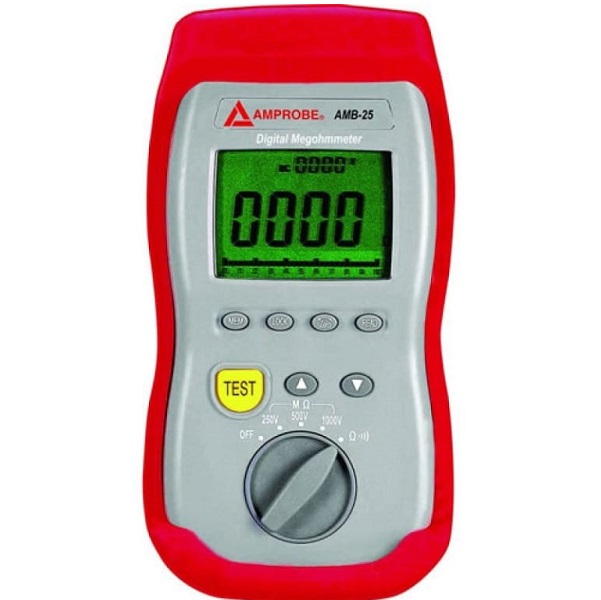

| Content | Use for Wire Tracer series AT-2000 | This affordable and rugged megohmmeter is fast and easy to use, and offer the features you need for most insulation test applications including wires, cables, transformers and motors. | The Amprobe SC-3500 4? Signal Clamp for AT-3500 attaches around a buried metallic pipe, cable, or wire to induce a transmitted signal into the feature for active location and tracing. It does not require direct contact with metal to transmit the signal and can transmit signal through insulation on wires and into cable and wire bundles, providing more accurate tracing than locating with just a receiver and transmitter. Accommodates conductors up to 4? in diameter. Transmits a 33 kilohertz (kHz) frequency supplied by the T-3500 Transmitter (included in the AT-3500 kit). | Keep productivity high and operational costs low, with the Amprobe AT-3500 Underground Cable Locator. It is the rugged, economical solution for locating cable, wires and pipes that are underground if they are energized or de-energized. Great for parking lot and airport lighting applications, it precisely pinpoints buried services, with exceptionally fast sound and meter response. The backlit, multiple-segment, bar graph, digital display, plus audible indicators easily locate cables and wires. The AT-3500 Underground Cable Locator employs the proven 33 kHz frequency for most locating applications. To avoid lines at utility construction sites, it also offers the highly sensitive power and radio modes. Take depth measurements with the simple press of a button. | Amprobe?s newest wire tracer combines a Receiver and powerful Transmitter to locate energized and de-energized wires, breakers, and fuses without having to disconnect any equipment. The Receiver features four tracing modes optimized for a range of applications. Its fully automatic breaker tracing capability saves time and eliminates the confusion of multiple false positives by detecting the highest recorded signal in a breaker or fuse. The Transmitter utilizes two optimized frequencies that allows for a clean and reliable signal. The Signal Clamp can be used in applications where there is no access to bare conductors by enabling the Transmitter to induce a signal into a wire through insulation. Whether you?re a novice user or an expert, the AT-6000 Amprobe Advanced Wire Tracer kit will help you get the job done fast. | The Amprobe LM-120 light meter measures the visible light from fluorescent, metal halide, high-pressure sodium or incandescent sources. It is a portable, easy-to-use digital light meter designed for simple one-hand operation reading in Lumen (lux) or foot candle (fc) units. The LM-120 measures a wide range of light up to 20,000 fc or 200,000 lux with an accurate, high resolution of 0.01 fc/lux. This unit is Auto-ranging plus manual ranging with ability to Zero out the reading before taking a measurement. |