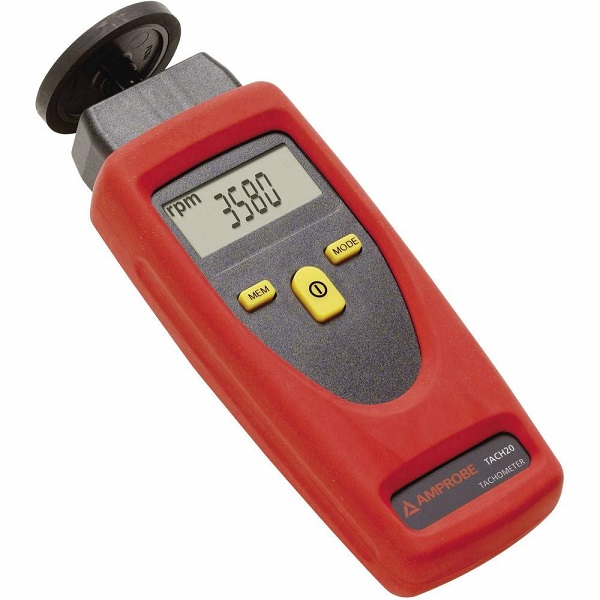

| Content | When leaks occur they often generate an ultrasonic frequency that is beyond human hearing. Amprobe?s TMULD-300 converts these sounds into an audible range for easy detection. The TMULD-300 tests pressurized air lines, refrigeration systems, and steam lines for leaks. Quickly and easily locate a leak location with this unique device. | | Like the AT-2004, the Amprobe AT-2005 Wire Tracer traces live wires buried or hidden behind walls up to 13 feet (4 m) thick without interrupting power. However, the AT-2005 electrical wire tracer also includes a battery booster that strengthens the signal for more accurately tracing opens and finding wires in walls. The AT-2005 is used for quickly locating breakers, broken wires, neutrals, grounds, shorts and pinpointing ground faults. | The Amprobe AMB-50 High-Voltage Insulation Tester has the necessary features for professional insulation diagnostics. It features calculation of PI and DAR parameters. The pass/fail comparison function helps to improve testing productivity. Readings are clearly displayed on a large backlit LCD display. Windows compatible PC Software and USB communications port serve for connecting the instrument to the PC and management of the recorded test data. | TEST LEAD SET FOR INSULATION RESISTANCE TESTERS | The Amprobe TACH20 Hand-held Tachometer accurately measures rotational or surface speed as well as length. It comes with a large LCD display that allows the user to easily read the measurement. It also has a built in memory function that permits automatic storage of maximum, minimum, average values plus the last measurement displayed. |

| Additional information |

| Weight |

3 lbs |

| Dimensions |

12.3 × 10.4 × 5.7 in |

|

| Weight |

2 lbs |

| Dimensions |

10 × 5 × 5 in |

|

| Weight |

8 lbs |

| Dimensions |

19.9 × 17.2 × 12.5 in |

|

| Weight |

6 lbs |

| Dimensions |

10 × 8 × 4.5 in |

|

|

| Weight |

1 lbs |

| Dimensions |

2 × 8.8 × 7.6 in |

|