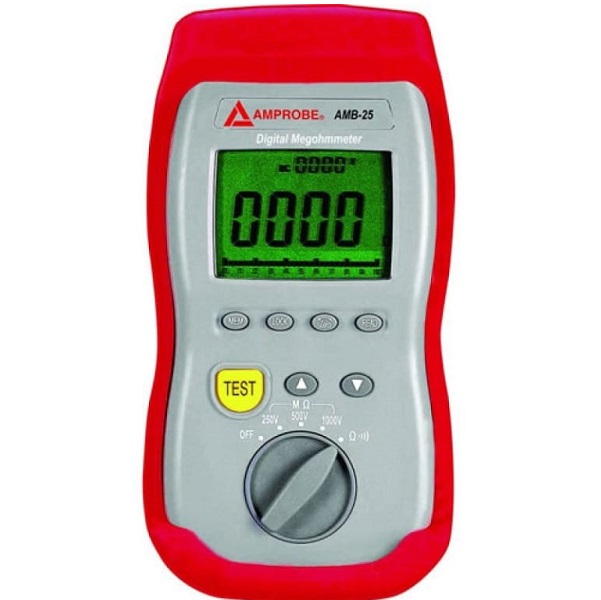

| Content | Amprobe Flex Current Sensor Developed for the Amprobe DM-5, your all-in-one solution for excellent power quality. | This affordable and rugged megohmmeter is fast and easy to use, and offer the features you need for most insulation test applications including wires, cables, transformers and motors. | The Amprobe SC-3500 4? Signal Clamp for AT-3500 attaches around a buried metallic pipe, cable, or wire to induce a transmitted signal into the feature for active location and tracing. It does not require direct contact with metal to transmit the signal and can transmit signal through insulation on wires and into cable and wire bundles, providing more accurate tracing than locating with just a receiver and transmitter. Accommodates conductors up to 4? in diameter. Transmits a 33 kilohertz (kHz) frequency supplied by the T-3500 Transmitter (included in the AT-3500 kit). | Keep productivity high and operational costs low, with the Amprobe AT-3500 Underground Cable Locator. It is the rugged, economical solution for locating cable, wires and pipes that are underground if they are energized or de-energized. Great for parking lot and airport lighting applications, it precisely pinpoints buried services, with exceptionally fast sound and meter response. The backlit, multiple-segment, bar graph, digital display, plus audible indicators easily locate cables and wires. The AT-3500 Underground Cable Locator employs the proven 33 kHz frequency for most locating applications. To avoid lines at utility construction sites, it also offers the highly sensitive power and radio modes. Take depth measurements with the simple press of a button. | | Poor grounding is dangerous and contributes to unnecessary downtime and increases the risk of equipment failure. The Amprobe GP-2A Earth Ground Resistance Tester provides accurate and reliable measurements for ground resistance and soil resistivity to assure the safety and performance of an electrical system. The GP-2A is complete with PC software that allows the user to download critical recorded measurements and to create professional reports for customers. |

| Additional information |

| Weight |

2 lbs |

| Dimensions |

10 × 10 × 10 in |

|

| Weight |

3 lbs |

| Dimensions |

12.3 × 7.8 × 4.5 in |

|

| Weight |

2 lbs |

| Dimensions |

9.84 × 9.84 × 9.84 in |

|

| Weight |

8 lbs |

| Dimensions |

30.7 × 14.6 × 14.2 in |

|

| Weight |

2 lbs |

| Dimensions |

10 × 5 × 5 in |

|

| Weight |

2 lbs |

| Dimensions |

12.4 × 8.3 × 6.6 in |

|